In our contemporary world, the role of materials science cannot be overstated, particularly when it comes to applications that operate under extreme conditions. Industries such as nuclear energy and military defense demand materials that exhibit remarkable resilience against factors such as high pressure, soaring temperatures, and corrosive environments. Hence, the pursuit of understanding the atomic and lattice-level behaviors of these materials becomes paramount. The modern quest is not merely about enhancing durability; it is about creating materials that offer increased performance, reduced weight, and sustainability.

Recent research conducted by scientists at Lawrence Livermore National Laboratory (LLNL) has shed light on the complex behaviors of zirconium when subjected to high-pressure environments. By compressing single crystal samples of zirconium, researchers discovered that the metal deformed in unexpectedly intricate ways. Their findings, published in the prestigious journals Physical Review Letters and Physical Review B, emphasize the importance of understanding how materials respond under stress, which is critical for developing new models of material performance.

Materials under severe stress experience various phenomena such as dislocation slip, crystallographic twinning, shear-induced amorphization, and fractures. These mechanisms allow the materials to dissipate shear stresses effectively. Saransh Soderlind, a lead author of the study, articulated the necessity of understanding these microscopic mechanisms: “They are fundamental for constructing predictive models for material performance under demanding conditions.”

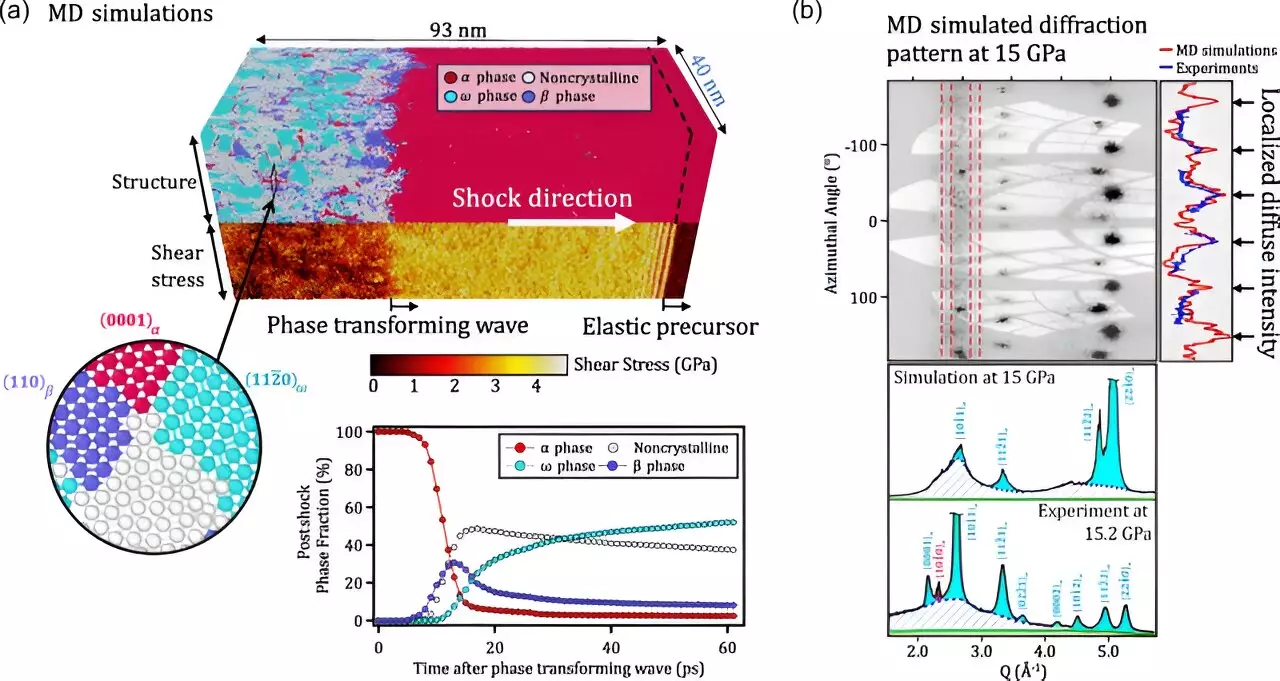

One of the most fascinating aspects of this research is the innovative experimental approach utilized by the LLNL team. By employing femtosecond in-situ X-ray diffraction, the researchers were able to observe the behavior of single-crystal zirconium being compressed over nanosecond timescales. To their surprise, they found evidence of atomic disorder—an unusual occurrence in elemental metals—and identified multiple pathways for phase transformations. This marked a groundbreaking moment, as such phenomena had not been documented in polycrystalline zirconium.

Further bolstering these findings were extensive molecular dynamics simulations employing a machine-learned potential. The computational support provided additional validation of the experimental results, leading to an enriched understanding of how metals deform under extreme conditions. LLNL scientist Raymond Smith noted, “This comprehensive picture of atomic movements is likely common across various materials when subjected to high pressures.”

Zirconium alloys play a crucial role in the nuclear industry, especially as fuel rod cladding due to their impressive strength and minimal neutron absorption. Moreover, their versatility extends to various harsh chemical environments, making them indispensable in several sectors. The implications of this research are far-reaching; it not only enhances our understanding of zirconium but potentially sets the stage for future innovations in material science.

As we strive to develop next-generation materials that are more efficient and sustainable, studies like this one illuminate the path forward. By grasping the underlying atomistic behaviors of materials such as zirconium under extreme conditions, researchers can pave the way for designing superior materials that meet society’s evolving demands. The intersection of advanced experimental techniques and computational modeling holds promise for unlocking new frontiers in materials science.