As the world of energy storage continues to evolve, sodium-ion batteries are emerging as a formidable alternative to the widely utilized lithium-ion systems. A recent breakthrough by a research team led by Dr. Daeho Kim and Dr. Jong Hwan Park at the Korea Electrotechnology Research Institute (KERI) could potentially propel sodium-ion technology to the forefront of next-generation battery solutions. Their innovative approach utilizes microwave induction heating to streamline the preparation of hard carbon anodes, a crucial component of sodium-ion batteries. With sodium being more abundant and environmentally friendly than lithium, this advancement is timely in addressing the growing needs for safe and efficient energy storage options.

Sodium-ion batteries hold several advantages over their lithium counterparts, notably the superior availability and ecological footprint of sodium. Sodium is easily sourced as it primarily derives from common salt, while lithium extraction processes are increasingly scrutinized for their environmental impact. The electrochemical stability of sodium also makes it encouraging for applications requiring quick charging and operational efficiency in low temperatures. Yet, despite these promising traits, sodium-ion technology faces significant hurdles, particularly in energy density and lifespan.

Manufacturing challenges arise primarily from the structural properties of sodium ions, which are larger than lithium ions. This necessitates the use of hard carbon for anodes, a synthetic material that must be engineered rather than naturally sourced. The traditional preparation of hard carbon involves complex and energy-intensive carbonization processes that demand temperatures exceeding 1,000°C in an oxygen-free environment, presenting both economic and environmental obstacles. To overcome these constraints, research teams worldwide aim to develop more efficient alternatives.

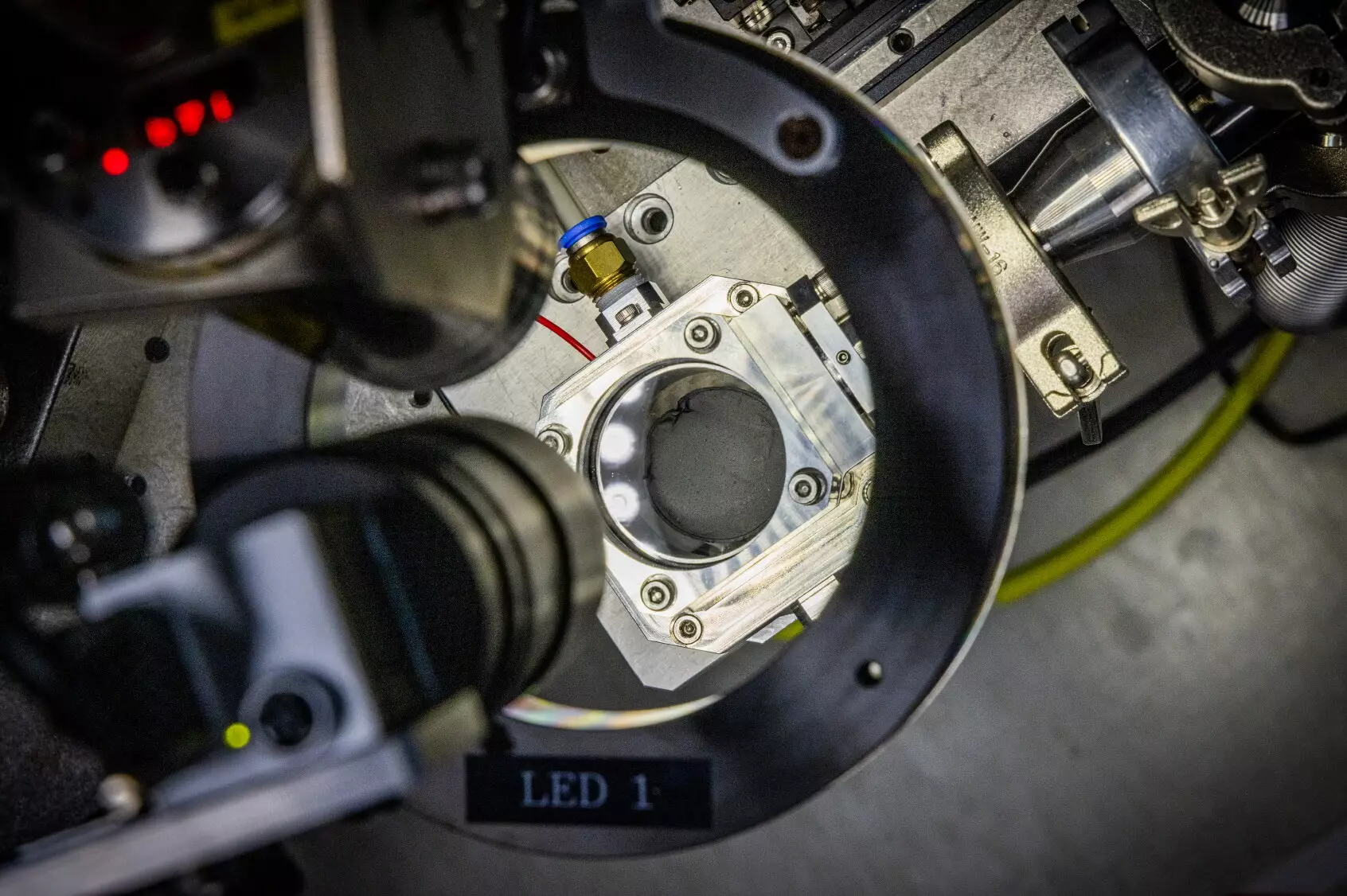

In this context, Dr. Kim, Dr. Park, and their team have embarked on a groundbreaking research initiative using microwave induction heating technology, more commonly associated with everyday kitchen appliances than industrial applications. The team’s methodology summarized succinctly involves creating composites by mixing polymers with conductive carbon nanotubes and applying focused microwave energy to achieve rapid heating. Their process reaches extreme temperatures of over 1,400°C in just 30 seconds, dramatically reducing production time and resource consumption.

KERI has established itself as a leading center for carbon nanomaterials research. The inclusion of “multiphysics simulation” techniques in their study has granted researchers comprehensive insights into the microwave-induced phenomena occurring within nanomaterials. This nuanced understanding ultimately facilitated the design of an efficient process for synthesizing anode materials for sodium-ion batteries—a feat that has garnered attention for its potential to revolutionize the battery industry.

Recent incidents of electric vehicle fires have heightened scrutiny surrounding lithium-ion batteries, subsequently amplifying interest in sodium-ion alternatives, particularly where safety and thermal stability are concerned. The rapid carbonization process heralded by the team at KERI could address these concerns, leading to the development of safer energy storage systems.

Despite the promising results, Dr. Kim and Dr. Park recognize that further enhancements are necessary to optimize the performance of the anode materials. Their vision extends to creating technologies that enable mass production of large-area hard carbon films, ensuring the scalable functionality of sodium-ion batteries. Furthermore, the microwave induction heating technology may also find applications beyond sodium-ion systems, such as in the development of all-solid-state batteries requiring high-temperature processing.

With a domestic patent application underway, KERI anticipates considerable interest from industry stakeholders involved in energy storage solutions. The prospects of technology transfer to industry partners could significantly advance the commercialization of sodium-ion battery technology while addressing the existing production challenges. The innovative work of Dr. Kim and Dr. Park illustrates a critical intersection between scientific research and pragmatic industry applications, paving the way for a greener, more sustainable battery landscape.

As the demand for efficient and safe energy storage solutions grows, the innovations emerging from KERI represent not just a leap forward for sodium-ion batteries but a transformative shift that could redefine energy storage paradigms across multiple sectors. With bold ambitions and proven results, this pioneering research effort promises to transform sodium-ion battery technology and, ultimately, the way we think about energy storage for the future.