As global awareness of environmental issues reaches new heights, the need for sustainable technology has gained unprecedented importance. In particular, the battery industry, which plays a pivotal role in powering everything from electric vehicles to portable electronics, is under scrutiny for its reliance on materials that are not only harmful to the environment but also detrimental to human health. Recent advancements from a research collaborative between POSTECH and Hansol Chemical have emerged as a hopeful solution to these pressing challenges. Their newly developed fluorine-free binder and electrolyte signal a significant shift towards eco-friendly and high-performance battery technology.

Challenges with Traditional Lithium Batteries

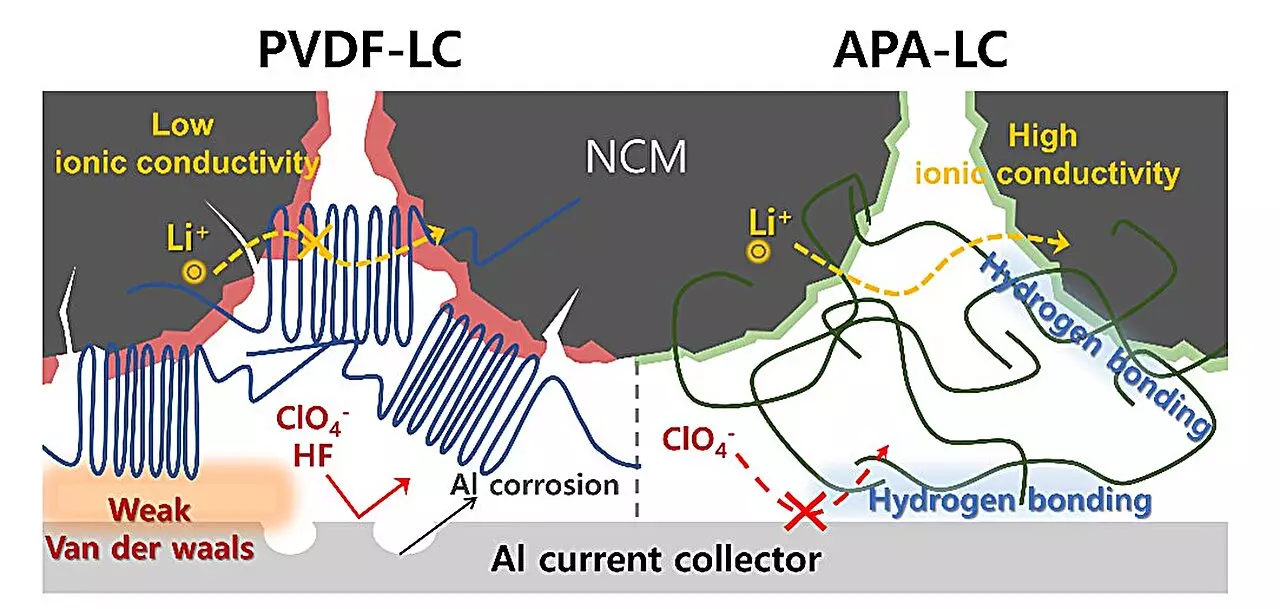

Traditional lithium-ion batteries commonly utilize fluorinated compounds such as polyvinylidene fluoride (PVDF) and lithium hexafluorophosphate (LiPF6) as binders and salts, respectively. While these materials have been instrumental in achieving current performance benchmarks, they come with substantial drawbacks. One major concern is their potential to release hydrogen fluoride (HF), a highly toxic byproduct that not only poses health risks during battery life but also limits the overall lifespan and efficiency of the battery. Additionally, both PVDF and LP are non-biodegradable, contributing to environmental pollution and complicating waste management processes.

With the EU moving towards stricter regulations on per- and polyfluoroalkyl substances (PFAS), there is a looming deadline for the battery industry to pivot to safer alternatives by 2026. This regulatory environment has intensified the need for innovative solutions that comply with legislative changes while enhancing battery performance.

Introducing the APA-LC System

The collaborative effort led by Professor Soojin Park and Seoha Nam has resulted in the creation of an alternative battery system that wholly eschews the use of fluorinated compounds. The researchers designed a lithium perchlorate (LiClO4, LC)-based electrolyte to replace the problematic fluorinated systems. Simultaneously, they developed a novel non-fluorinated aromatic polyamide (APA) binder. This dual approach forms the backbone of the new “APA-LC” system, which not only complies with environmental mandates but also promises marked improvements in battery performance.

The APA binder enhances the connection between the active materials in the cathode and the aluminum current collector. This reinforcement helps diminish electrode corrosion, thus dramatically increasing the longevity of the battery. Along with the introduction of lithium chloride and lithium oxide in the LC system, this innovative combination fosters improved ion migration — a critical component for optimizing overall battery output and charge times.

In terms of quantifiable outcomes, the APA-LC battery system has demonstrated remarkable results. The new configuration exhibited greater oxidation stability compared to the conventional PVDF-LP setup. When put through rigorous testing over 200 cycles at rapid charge and discharge rates, the APA-LC system retained an impressive 20% higher capacity. Furthermore, this was accomplished within a voltage range of 2.8–4.3 volts during standard coin cell assessments.

The culmination of this research led to the production of a 1.5 Ah pouch cell that not only maintained exceptional energy discharge capabilities but also excelled in fast-charging scenarios. This development marks a significant milestone in battery technology, showcasing a feasible, environmentally friendly approach that can potentially dominate the market.

The achievement is significant for multiple reasons: it challenges the status quo of battery materials, aligns with regulatory pressures, and opens up exciting market opportunities. Young-Ho Yoon, the Managing Director of Hansol Chemical’s Secondary Battery Materials Business, emphasized that addressing PFAS concerns has positioned them strategically in the global cathode binder market, which is projected to explode to KRW 1.7 trillion by the year 2026.

Professor Soojin Park’s assertion encapsulates the essence of this breakthrough: the APA-LC solution is not merely a workaround; it exemplifies a genuine advancement in battery sustainability. As industries evolve and environmental stewardship becomes paramount, this innovation will likely act as a catalyst, prompting a broader shift towards non-fluorinated systems without compromising performance.

As we navigate the complexities of technological advancement and ecological responsibility, the APA-LC system stands as a testament to what can be achieved when innovation meets necessity. With continued dedication to research and development, the future of battery technology appears not only promising but also truly sustainable.