At the forefront of robotic innovation, the Interactive and Robotic Systems Lab (IRS) at Universitat Jaume I (UJI) in Castellón has unveiled a pioneering mobile manipulator robot. This advanced technology is lightweight, modular, and can be reconfigured for diverse applications. Its design optimizes both versatility and efficiency, making it suitable for critical inspections, particularly in hazardous environments where human intervention poses significant risks. The robot integrates a comprehensive remote control station, equipped with 3D perception capabilities, ensuring operators have precise control and visualization as they navigate through complex settings.

The development of a cutting-edge multi-device 3D simulation software, which includes a digital twin for training operators, marks a significant leap in the application of robotics. This feature not only enhances the training experience by allowing users to simulate missions but also ensures that they acquire the necessary skills in a safe environment. By refining their competence before actual deployment, operators can significantly reduce the likelihood of errors when engaging with the manipulator robot in real-world scenarios.

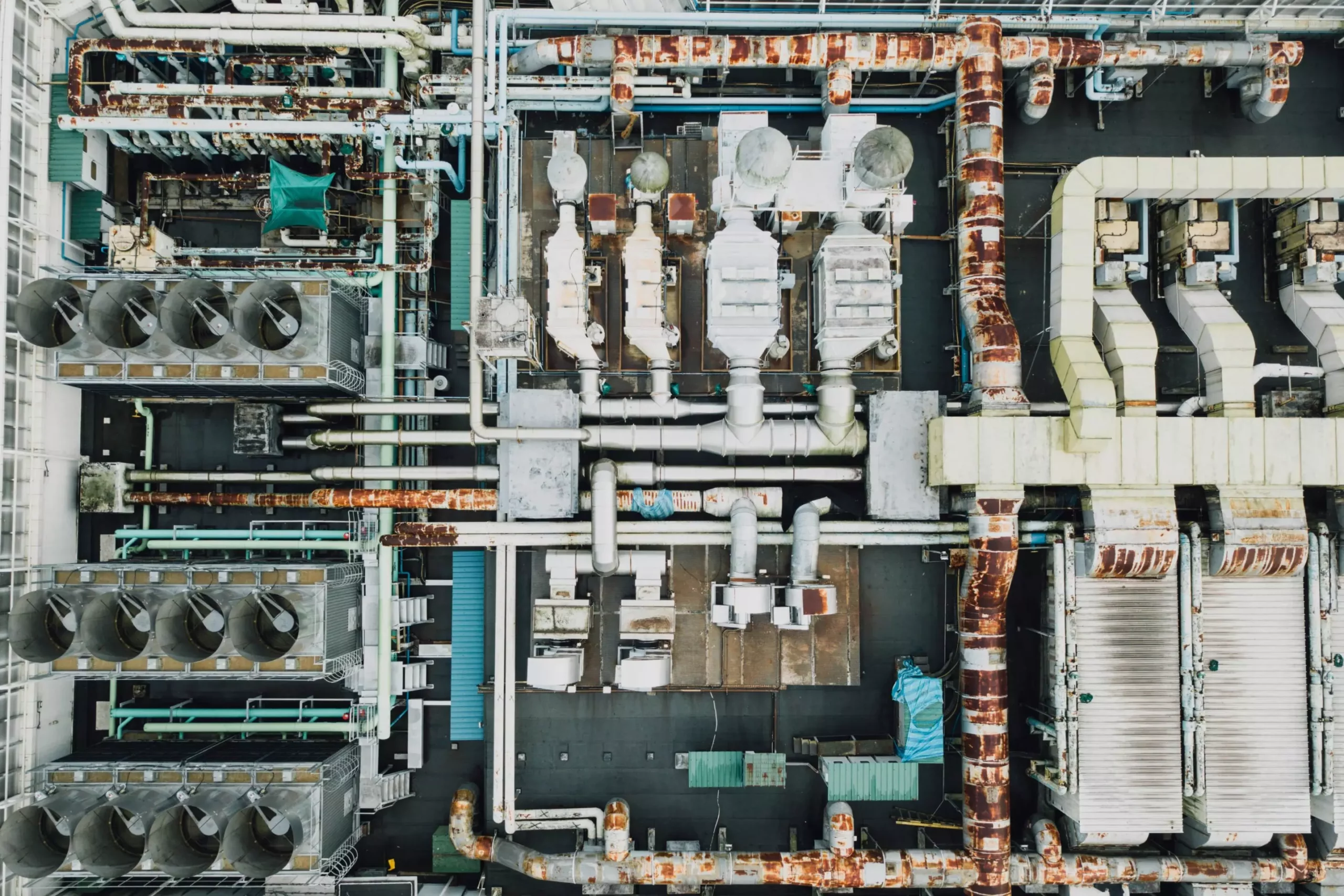

The IRS group’s innovation has been systematically validated at UJI’s Centre for Research in Robotics and Underwater Technologies (CIRTESU). Its initial application involves the inspection of plastic pipes, utilizing probing methods alongside advanced visual processing. This functionality is crucial for environments such as nuclear power plants and particle accelerators, where the integrity of plastic piping systems is paramount. Additionally, the robot’s adaptability extends its potential use in teaching and healthcare settings, particularly in infectious zones, showcasing the system’s broad applicability in varied hazardous circumstances.

Significant advancements in both software and hardware have bolstered the robot’s operational capabilities. The system is equipped with a Robot Operating System (ROS)-based server alongside multiple client interfaces, facilitating mission-specific customization. In terms of hardware, the implementation of wireless communications, diverse vision devices, and refined localization techniques solidify the robot’s operational efficacy. It maintains low weight and power consumption, ensuring energy efficiency and mobility. Notably, the open architecture promotes modularity, allowing for scalable adaptations to suit unique operational requirements while keeping production costs manageable.

The project, branded under the European initiative “EU H2020 El-Peacetolero,” signifies a collaborative effort alongside eight other European institutions, underscoring the importance of international partnerships in advancing technological innovation. Furthermore, UJI actively supports commercial partnerships through its Cooperation and Technological Development Office, streamlining the transition of technological developments into real-world applications. Such mechanisms pave the way for tailored adaptations and licensing agreements with corporations, ensuring that research translates into tangible benefits for society.

The research achievements at the Interactive and Robotic Systems Lab reflect a forward-thinking approach to robotic solutions in hazardous environments, reinforcing UJI’s commitment to scientific dissemination and innovation. Such initiatives not only enhance operational safety but also demonstrate the essential role of technology in modern scientific and industrial landscapes.