As the world increasingly shifts towards renewable technologies, the demand for rare-earth elements (REEs) has surged. These elements, particularly neodymium (Nd) and dysprosium (Dy), are fundamental in the creation of high-performance magnets that underpin various green technologies, such as electric vehicles (EVs) and wind turbines. However, the rapid growth in demand highlights a significant challenge: how to efficiently recycle these critical materials from end-of-life products. Researchers from Kyoto University have proposed a provocative solution encapsulated in their study, emphasizing a new method known as the selective extraction–evaporation–electrolysis (SEEE) process.

The SEEE process presents a transformative fourth option to traditional methods of extracting rare-earth minerals from spent magnets. Common practices have often relied on hydrometallurgical processes, which can be not only complex and energy-intensive but also environmentally harmful. Professor Toshiyuki Nohira and his team at the Institute of Advanced Energy have staked a groundbreaking approach with SEEE, one that integrates principles of sustainability with practical efficacy, promising up to a 96% recovery rate for neodymium and a 91% rate for dysprosium.

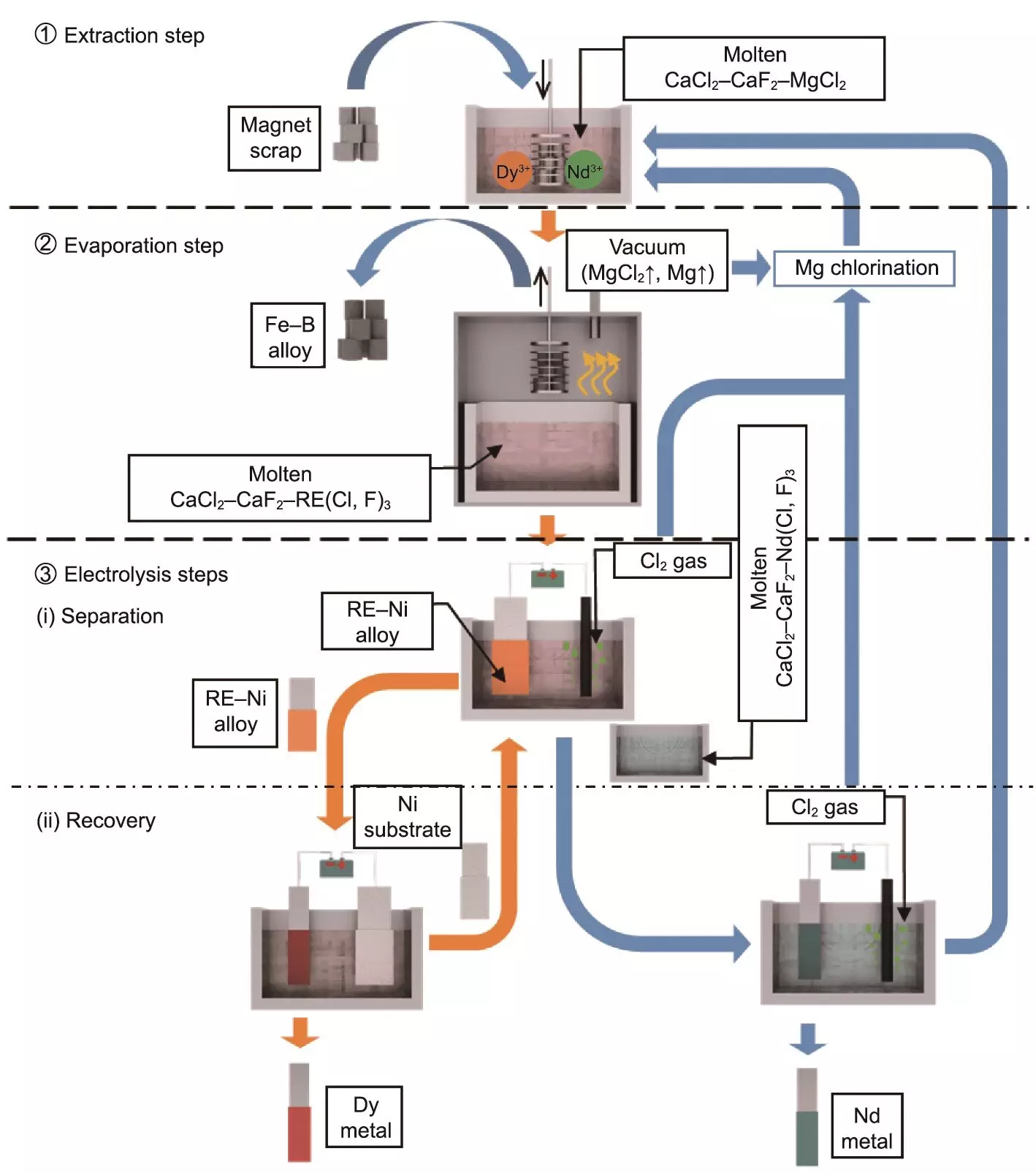

The SEEE process unfolds across three distinct stages:

1. **Selective Extraction:** This initial stage utilizes a molten salt mixture, predominantly calcium chloride (CaCl2) and magnesium chloride (MgCl2), to dislodge and extract REEs from scrap magnets. By introducing calcium fluoride (CaF2), the team manages evaporation losses effectively, which in turn enhances overall extraction efficiency.

2. **Selective Evaporation:** Following extraction, the method eliminates remaining agents and byproducts. This step concentrates the REEs, setting the stage for the final purification phase.

3. **Selective Electrolysis:** In the concluding stage, an electrochemical process facilitates the separation of extracted REEs based on their formation potentials. This precision allows for the recovery of high-purity metals, essential in meeting the stringent requirements of modern technology applications.

The findings from this recent study underscore the SEEE process’s potential to revolutionize the recycling landscape. Achieving purification rates above 90% positions it significantly ahead of conventional recycling methods previously used for Nd and Dy. Such advancements are not merely academic; they resonate within industries grappling with the supply chain concerns of REEs.

With the burgeoning need for resources in electric mobility and renewable energy production, transitioning away from mining—often associated with detrimental environmental impacts—becomes a compelling strategy. The novel SEEE process holds promise not only to provide a steady supply of REEs but also to mitigate the ecological costs tied to their initial extraction.

Yet, the scope of the SEEE process could extend well beyond the realm of magnet recycling. The research team suggests potential applications in other sectors, notably in nuclear fuel reprocessing. The adaptability of this method could signify broader industrial utility, ultimately enhancing resource recovery across various technologies.

While the SEEE process’s current results are promising, it is crucial to acknowledge the hurdles that remain before implementation on an industrial scale. Further research and technical assessments are necessary to ascertain the feasibility and efficiency of the process within a commercial framework.

Despite these challenges, the innovation represented by the SEEE process is an important step towards harmonizing technological advances with sustainable practices. The authors recognize that creating pathways for efficient recycling is instrumental in meeting global environmental objectives, especially as countries aim to achieve carbon neutrality.

Kyoto University’s groundbreaking research into the SEEE process provides valuable insight into the future of rare-earth element recycling. As society continues to embrace green technologies, the imperative for effective recycling solutions becomes increasingly vital. Innovations like SEEE not only pave the way for enhanced resource sustainability but also signify an essential stride toward a balanced relationship between technology and the environment. Through continued technical exploration and adaptation, we can hope for a future where recycling meets the escalating demands of our modern technological landscape without compromising ecological integrity.