Recent advancements in concrete research have opened exciting new possibilities for the use of ultra-high-performance concrete (UHPC) reinforced with fiber-reinforced polymers (FRP). A significant study published in the journal Engineering, spearheaded by researchers S.S. Zhang, J.J. Wang, Guan Lin, and X.F. Nie, presents an innovative analysis-oriented stress–strain model that enhances our understanding of UHPC’s compressive behavior when subjected to confinement by FRP. This development is crucial as the construction industry increasingly relies on the remarkable qualities of UHPC for modern engineered structures.

UHPC is celebrated for its tremendous strength and exceptional durability; however, integrating it with FRP materials posed a substantial challenge in structural engineering. Traditional stress–strain models, which were adept at addressing normal-strength concrete (NSC) within a confined framework, fell short when applied to UHPC. The discrepancies in understanding this new material necessitated a reevaluation of existing models to better accommodate the unique behaviors exhibited by UHPC under stress.

The study, involving researchers from Huazhong University of Science and Technology and Southern University of Science and Technology, meticulously questioned long-held assumptions about concrete behavior. The aim was to delineate how UHPC adapts under concentric compression when reinforced with FRP, thus providing a clearer picture of its mechanical performance.

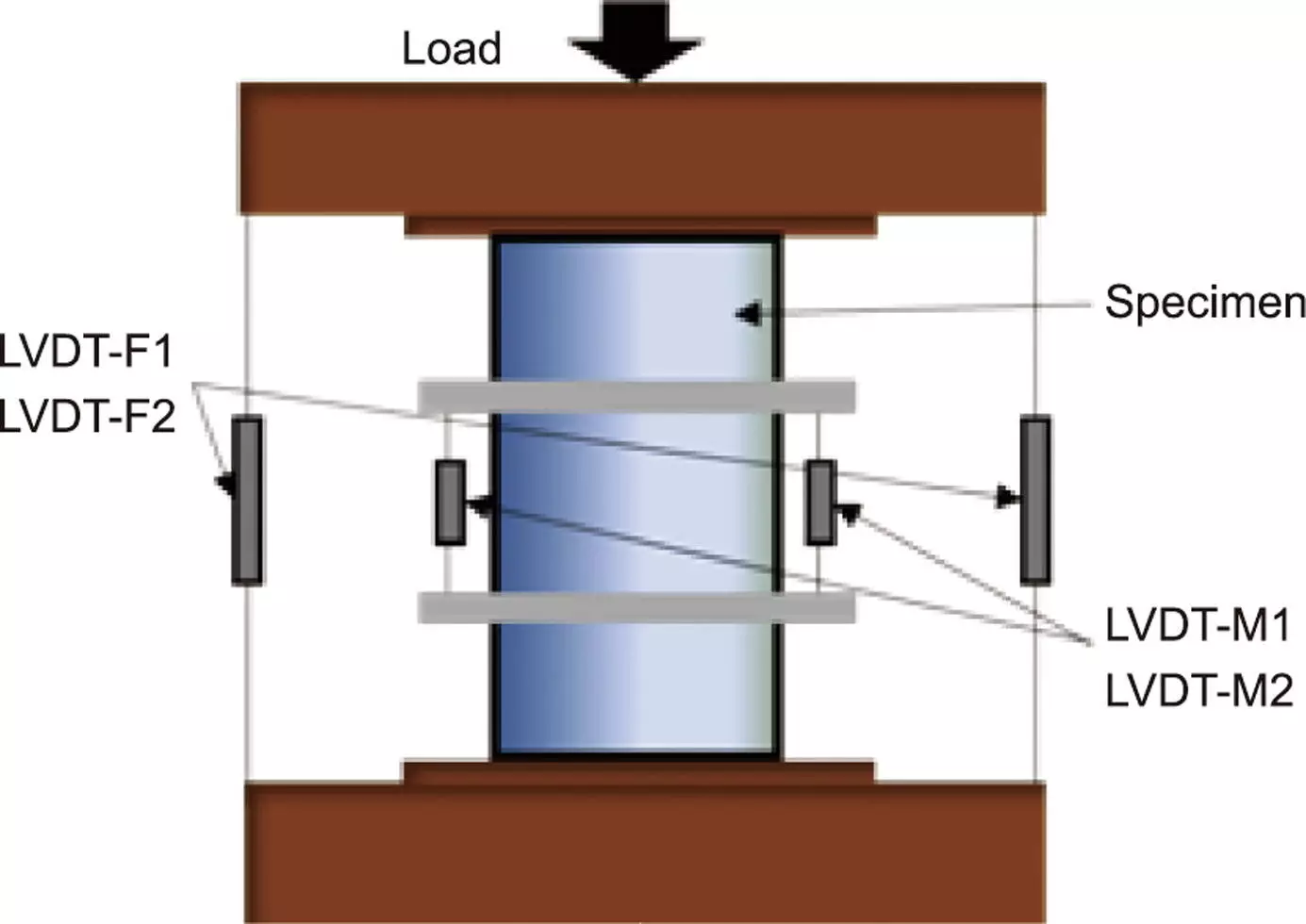

Through rigorous experimentation, the research team discovered that the commonly accepted principle of stress-path independency—a key assumption for models regarding FRP-confined NSC—did not hold up under the conditions affecting UHPC. One of the pivotal findings was the role of major diagonal cracks that emerged in the FRP-confined UHPC specimens, leading to non-uniform lateral expansion. This physical behavior triggered a reduction in effective confining pressure, raising questions about the previously accepted paradigms that had underpinned NSC analysis.

The researchers meticulously adjusted their approach, leading them to develop a new model equipped to consider the nuances of stress-path dependency. By incorporating a revised equation that accounted for the confining pressure gap, the model became a more accurate tool for predicting the compressive behavior of UHPC confined by FRP.

To ensure the reliability of their newly proposed model, the researchers conducted extensive testing against a robust database of previously collected test results. This validation process was critical, as it revealed an impressive alignment between the predicted stress–strain behavior of FRP-confined UHPC and actual experimental outcomes. The enhanced predictive capabilities of this model signify a marker of progress in structural engineering, offering engineers a dependable framework for both designing and analyzing UHPC-based structures.

The implications of this study extend beyond mere academic achievement; the accurate forecasting of UHPC’s behavior under stress could reshape construction practices and architectural outcomes across a multitude of applications. As engineers leverage this refined model, the drive towards creating safer and more efficient structures is poised to accelerate.

The advent of this analysis-oriented stress–strain model represents a significant leap in the understanding of high-performance concrete technology. Not only does it present a clearer understanding of UHPC under confinement, but it also sets the stage for future innovations in composite materials and construction techniques. As industries strive for greater sustainability and resilience, the insights gained from this research could steer new avenues of exploration—fostering advancements that are sustainable and structurally sound.

The contributions made by this study to the field of structural engineering are impressive and necessary. By effectively addressing the complexities associated with UHPC confined by FRP, researchers have provided invaluable tools for engineers and researchers poised to redefine the nature of concrete applications. With continued evolution in the construction sector, this new model is destined to influence how structures are conceived, executed, and evaluated for years to come.