Electric motors, particularly small ones, are ubiquitous in both daily life and industrial applications. Found in household devices, power tools, computing equipment, and particularly in automobiles, these motors facilitate the operation of vital components such as water pumps and fan systems. While each individual motor may draw a negligible amount of power, the aggregated contribution of these motors represents a significant opportunity for energy savings. A recent advancement in this domain has arisen from the research conducted by a forward-thinking team at Graz University of Technology co-led by Annette Mütze. Their work in the “CD Laboratory for Brushless Drives for Pump and Fan Applications” underscores the necessity and potential benefits of optimizing electric motor technology.

The research team has harnessed cutting-edge design methodologies and control technologies to enhance the operating efficiency of brushless integrated drives. These innovations have led to motors that not only consume less energy but also perform more quietly and are lighter than traditional counterparts. The incorporation of larger claw pole motors, often used in automotive lighting systems, has expanded their application range. Mütze and her team achieved substantial improvements by addressing the “cogging torque” phenomenon, known for causing roughness in motor operation. Through skewing and slotting the serrated claws of these small drives—without incurring extra costs—they have successfully reduced the abrupt engagement of claws. This modification diminishes unwanted vibrations, leading to noise reductions of about 70%. Mütze asserts that these enhancements result in drives that operate more smoothly, thus enriching the user experience.

A core component of the advancements made by Mütze’s team is a reimagined way to regulate current flow in these motors. Traditional techniques for controlling motor operations, often based on pulse width modulation, involve frequent switching that inadvertently spikes energy consumption. By streamlining this process—switching the drives on and off a limited number of times per operational cycle—the team has achieved significant reductions in switching losses. This adjustment is especially beneficial at lower currents, where the electric motors demonstrate markedly enhanced efficiency compared to their traditional counterparts that rely on continuous pulse width modulation.

Furthermore, this novel approach allows the motor circuitry to utilize fewer capacitors, halving the component count necessary for effective operation. This reduction not only simplifies the design but also contributes to lowering overall manufacturing costs, thereby promoting economic viability in the adoption of these improved electric motors.

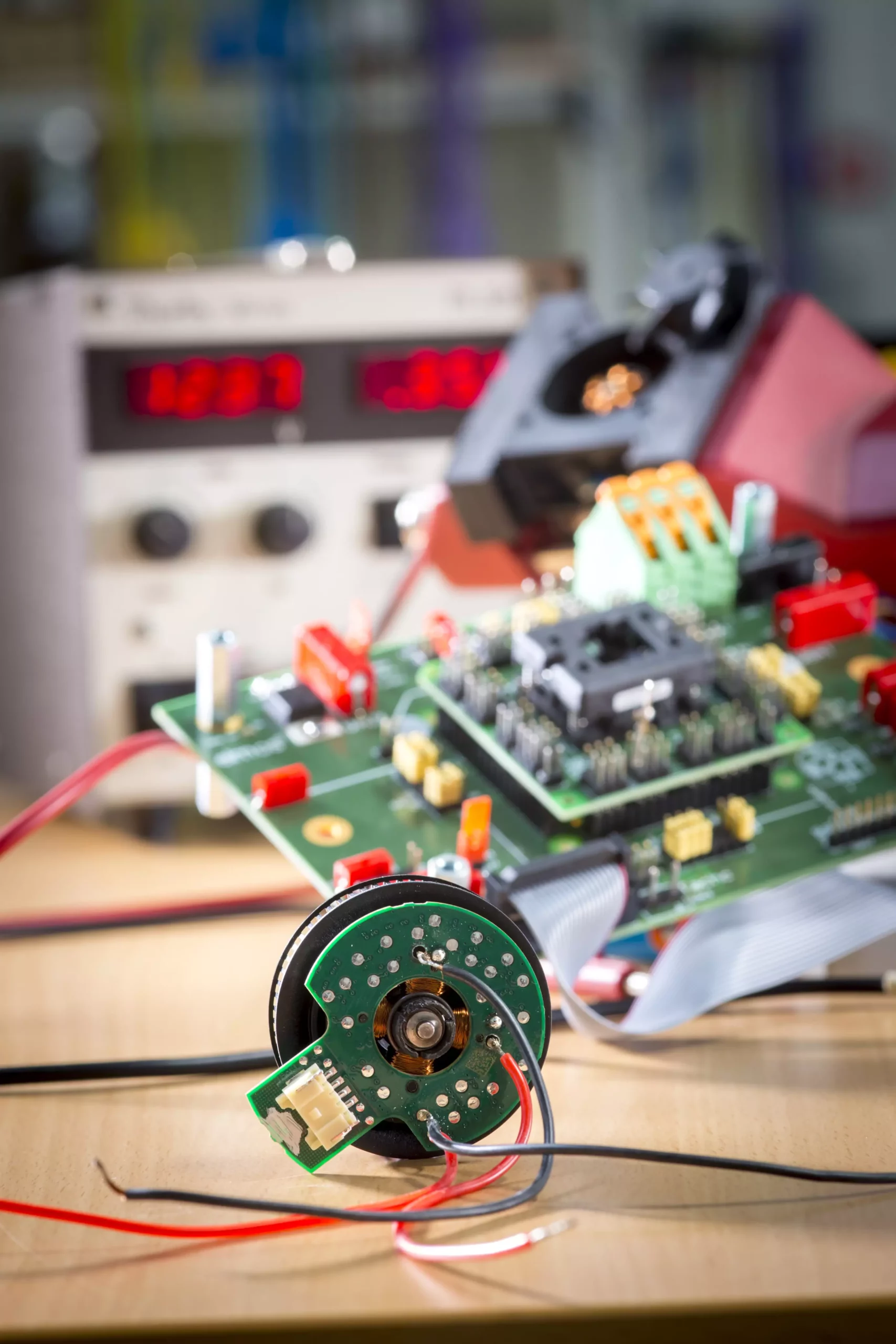

The methodological innovations extend into the realm of manufacturing practices, particularly with the introduction of printed circuit board (PCB) motors that utilize ferrite cores. By redefining the structural framework of motor windings and integrating them as part of a printed circuit board, the team can leverage automation to enhance production efficiency. This integration fosters rapid and adaptable manufacturing processes while maintaining high-quality output.

The team has further enhanced these PCB motors by employing 3D-printed ferrite cores, optimizing the magnetic field’s flow within the motor. This technical improvement is crucial—it enables the utilization of more cost-effective ferrite-based magnets. By creating a pathway for more efficient magnetic flux management within the drive system, Mütze’s innovations contribute to both performance and affordability.

The research spearheaded by Annette Mütze and her team at Graz University of Technology represents a significant leap forward in the design, efficiency, and operational quietness of brushless electric motors. By addressing issues like cogging torque and streamlining current flow regulation, they have created a new standard in motor technology. The combination of innovative design techniques, manufacturing process advancements, and efficiency improvements sets a promising foundation for future developments in electric motor applications across various sectors, fostering both sustainability and economic effectiveness. As the world continues to prioritize energy conservation and intelligent design, these strides in electric motor technology will undoubtedly play a pivotal role.